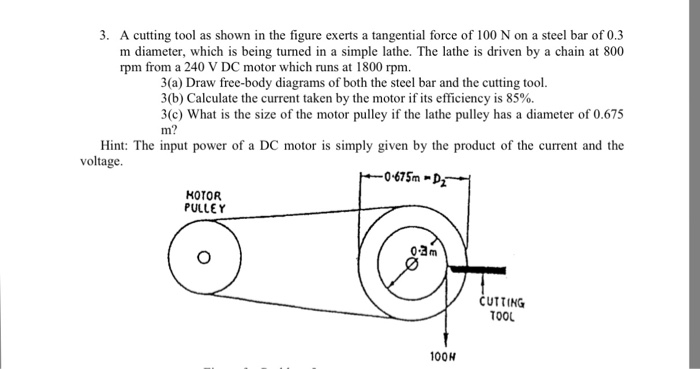

The Cutting Tool On The Lathe Exerts A Force

As a follow-up to my April column, here are additional tips for enhancing the operation of a manual lathe. Sony Ericsson Unlock Patch. Multipurpose tool bits, such as this one that turns ODs. Answer to The cutting tool on the lathe exerts a forceon the shaft as shown.Determine the moment of this force about the y axis. Drivers Superbox X more.

Repad: Welcome to a great forum and you will get excellent advice here--far more knowledge than I have. Genius Cp-sf600 Driver For Windows 7 64 Bit here. A couple things that help me. Be sure your parting tool is on center (I like to use a 6' scale and trap it between the work and parting tool---when it is straight up--you are good to go). Be sure tool is sharp 3.

Feed by hand and slowly at first--you will develop a 'feel' for feed rate 4. Lots of good hss parting blades--I use Empire but others are fine 5. Keep parting tool as short as possible--just enough overhang to cut the material--rigid set up. One thing no one has mentioned is the type of toolpost. The old style so called 'lantern' or 'rocker ' toolposts are useless.

They can be made to work and I did a lot of turning with them, but once I got a modern one, they became relics. Besides an Aloris toolpost, I have made a number of blocks with a hole to bolt them down to the compound and then chucked a 3/4' end mill in the spindle and cut a slot for the bit. I drill and tap some holes in the top for screws to lock the bit in place and use 3/8 bits, which come right out on center. Like Tom, I do a lot of that sort of parting with a 3/8' bit ground to a narrow blade.